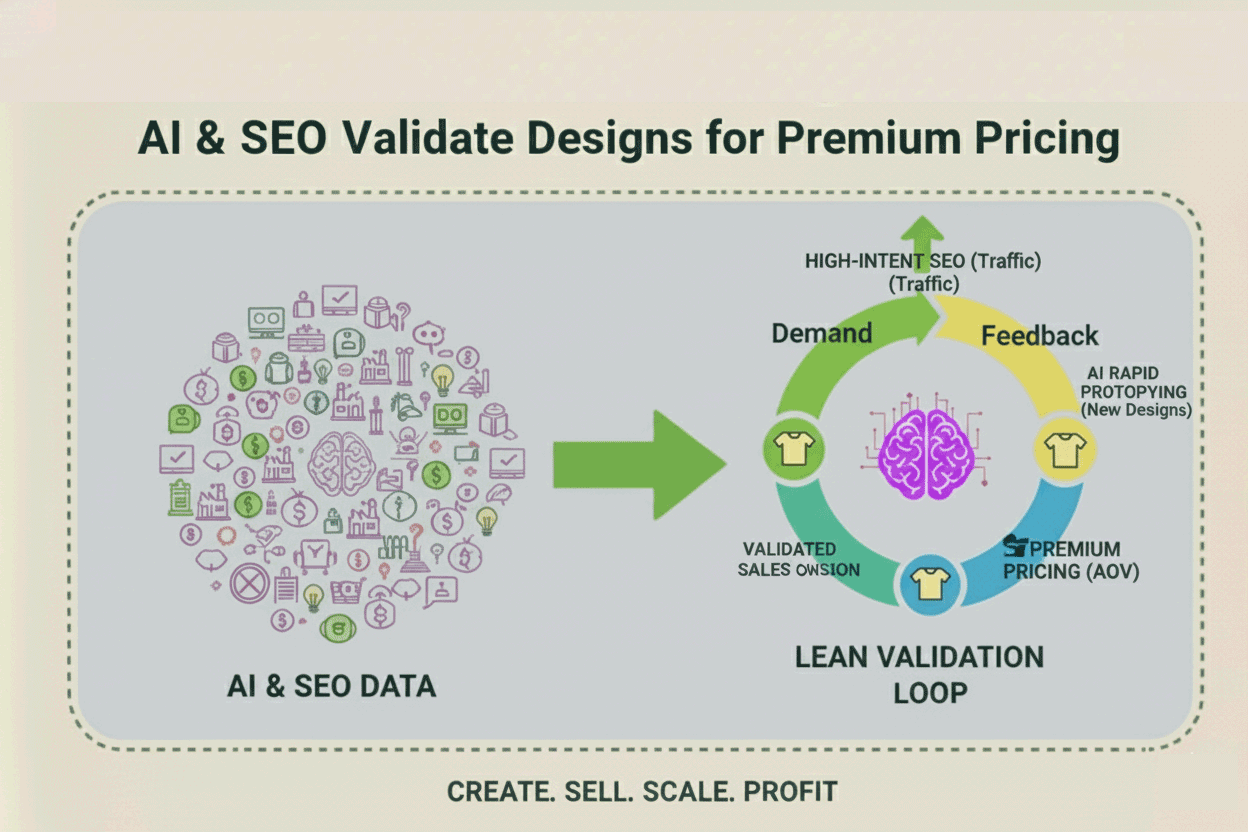

You have successfully executed the BUILD (launch lean) and MEASURE (validate with data) phases. Your designs are selling, and you’ve proven product-market fit within your hyper-niche. Now, the final phase—LEARN—is about optimizing your successful efforts for maximum margin and long-term defensibility.

Your objective is to push your profitability far beyond the industry’s average of 20% by strategically leveraging two core pillars: verifiable sustainability and high-margin product diversification.

The Dual Price Multiplier: Personalization + Sustainability

The foundation of any premium e-commerce brand is its ability to command premium pricing. For the lean founder, this is supported by a dual commitment that speaks directly to the modern consumer's values: customization and ethical production. Consumer data unequivocally supports this strategy: 81% of consumers will pay extra for custom apparel, and a staggering 80% of consumers globally will spend more for sustainable products. Your strategic task is to credibly communicate this commitment to sustainability to capture what is known as the "Green Premium."

The Sustainability Credibility Check: Moving Beyond Vague Claims

The primary, most defensible sustainability claim inherent to the POD model is waste reduction. By definition, producing items only after a purchase is confirmed eliminates 100% of inventory waste compared to the traditional retail model, which often results in unsold stock being sent to landfills. This is your core advantage. However, to achieve a true Green Premium, you must build upon this foundation with specific operational choices:

- Partner Selection as a Core Ethical Choice: Your choice of fulfillment partner is a direct extension of your brand’s ethics. Select partners whose core business model aligns with verifiable sustainability. TPOP is a strong candidate, as it mandates the use of water-based inks and eco-responsible packaging, including compostable mailers and the use of kraft paper adhesive instead of less sustainable plastic tape. For emissions reduction, Gelato is an ideal platform because its global network facilitates local production, minimizing shipping distances and associated carbon emissions.

- Printing Technology Transparency: Educate your customers about the technology you use. Highlight the use of water-based pigment inks (common in DTG/DTF), which are non-toxic and significantly reduce Volatile Organic Compounds (VOCs) compared to older, solvent-based printing methods. This detail, while technical, reassures the premium customer that your production process is cleaner.

- Messaging and Verification: The Path to Authentic Trust: Focus on certified materials (e.g., Oeko-Tex Standard 100 or certified organic cotton). To build high-level credibility, share specific, verifiable third-party proof, such as Science Based Targets (SBTs) held by your suppliers. An authentic sustainability journey is an ongoing one. By communicating your continued efforts toward improvement, you establish defensible, long-term trust with the premium customer, justifying the higher price point.

Strategic Product Diversification for Margin Expansion

Once a design is validated—meaning it consistently achieves a high Design Conversion Rate (DCR) and contributes positively to Average Order Value (AOV)—you must cease testing its viability and immediately pivot to monetizing its success across higher-margin product categories. The single greatest mistake of a scaling POD founder is relying solely on apparel. T-shirts, hoodies, and basic home décor are essential for market validation, but they will never achieve the margin potential of specialized accessories.

The Strategy: Pivot to Specialized, High-Ticket Accessories

The most substantial and rapid margin gains are found by deploying your winning design assets onto specialized, high-ticket items. Your "winning design" is an asset; the goal is to extract the maximum revenue from this asset with minimal additional creative work.

The transition to accessories focuses on maximizing the difference between the retail price and the fulfillment cost:

| Product Category | Example Retail Price | Fulfillment Cost | Potential Profit Margin | Strategic Impact |

|---|---|---|---|---|

| Personalized Jewelry (Necklaces/Rings) | $80+ | $5 - $30 | 70% to 100% | Drastically raises Average Order Value (AOV). High perceived value. |

| Customized Watches | High Ticket ($100+) | Variable | High | Positions brand in luxury/gift segment, ideal for holidays. |

| Specialty Home Goods (e.g., Custom Photo Canvas, Engraved Cutting Boards) | Variable | Variable | High | Maximizes revenue from one design file with minimal creative effort. |

Personalized jewelry and customized watches offer exceptional profitability that redefines a store's financial profile. Personalized rings, for instance, can retail for up to $80 while having low fulfillment costs, allowing for potential profit margins ranging from 70% to 100%. This zero-cost deployment of a validated design file onto a high-ticket item is the most efficient mechanism for lifting your store’s overall profitability far beyond the industry standard.

"The single greatest mistake of a scaling POD founder is relying solely on apparel."

To execute this strategy, partner with specialized POD providers: Look for ShineOn (for jewelry) or JetPrint (for custom watches). These platforms are built specifically to handle the complexities and high quality required for luxury-adjacent accessories, allowing you to maintain your lean, inventory-free model while tapping into luxury margins.

The Strategic Decision to Scale In-House

The final lesson in the LEARN phase is knowing when (and, more importantly, when not) to commit to heavy equipment. The lean path remains firmly Partner First until the cold, hard data demands a complex operational change.

The threshold for considering in-house production is extremely high. You should only consider moving to in-house production when a single product design consistently achieves a high, sustained sales volume (e.g., hundreds of units monthly) that is now severely compressing your margins due to third-party fulfillment fees. This is not a decision based on intuition; it is a calculation based on cost.

This transition must be supported by a rigorous break-even analysis. The analysis must prove, with absolute certainty, that the savings in per-unit cost from running your own mid-range equipment ($7,000–$15,000 for a quality DTG or DTF setup) decisively outweigh the significant increase in operational complexity.

The hidden costs of "going in-house" are often underestimated by new entrepreneurs:

- Labor Commitment: Even mid-range equipment requires a minimum of 20–30 minutes of daily maintenance and dedicated time for production, quality control, and packing. This is time taken away from marketing and design.

- Operational Risk: The risk of equipment downtime, costly repairs, and consumables management is entirely absorbed by the business. When a third-party partner’s machine breaks, you simply switch suppliers; when your machine breaks, your store stops selling.

- Inventory Creep: You must now manage inventory of blank garments, inks, pre-treatment solutions, and spare parts, reintroducing a level of inventory risk the POD model was designed to eliminate.

Until that clear, data-driven threshold is crossed—when the third-party fees are undeniably costing you more than the total cost of ownership (TCO) for your own equipment—the lean strategy dictates that you continue to outsource fulfillment. Your resources must remain dedicated to what generates revenue: market growth, customer acquisition, and strategic product diversification.

Your Final Action Plan: Learn to Scale

The transition from a struggling startup to a successful scale-up is defined by operational discipline. By focusing on these three strategic leverage points, you move beyond mere survival and establish a defensible, high-profit POD brand ready for long-term growth.

By mastering these elements, you successfully complete The Lean Founder’s POD Profit Accelerator series, establishing a resilient and profitable brand built on validated demand, premium pricing, and sustainable 30%+ margins, setting the stage for long-term growth and success.

No comments yet

Be the first to share your thoughts on this article!